Redesign a sewing machine in a way that will physically improve the task of sewing.

Journey mapping the process of sewing showed the most difficult stages being assembly and sewing. Anthropometric studies were conducted showing the posture of the user while sewing and became apparent the posture is extremely hunched over when needing to look at smaller details common when sewing. Anywhere form 5 minutes up to 2 hours on a domestic sewing machine resulted in back pains and aches.

Product Autopsy

Deconstruction of a sewing machine. My main take away from this was learning about the crutial connection between the bobbin mechanism with the pivoting needle arm. If i am able to find a way of seperating these many parts could be removed and simplify the mechanism.

Began sketching concepts for a sewing machine that had adjustable heights to improve posture. Separating the bobbin from the sewing plate so the needle was able to move while then height was adjusted.

Prototyping

Pototyping using polystyrene, cardboard and modelling foam.

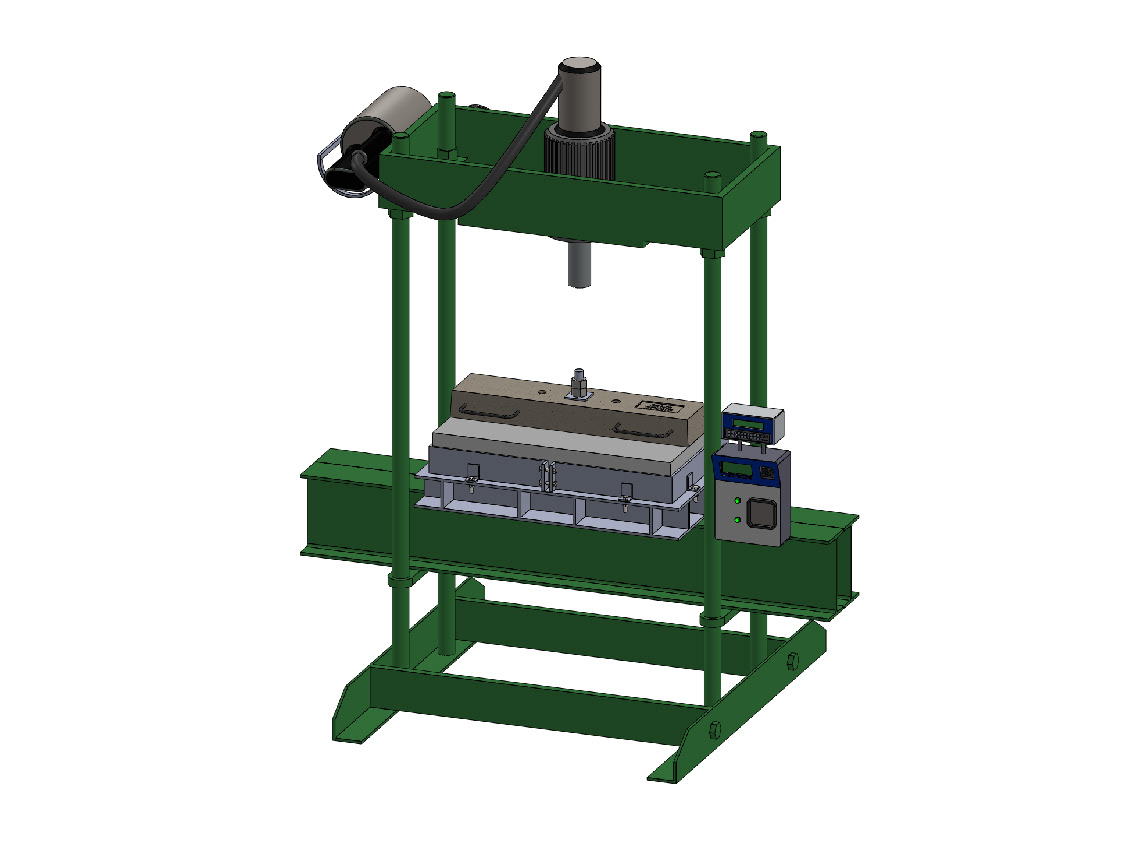

Final Design.

Rousch sewing machine is able to adjust the height of the needle and sewing plate bringing the details closer to the users line of sight without needing to hunch over as much. Reducing the angle of the neck by up to 20 degrees.

Modelled in Rhino and rendered using Solidworks Visualize.